About

What we do and why?

Overview

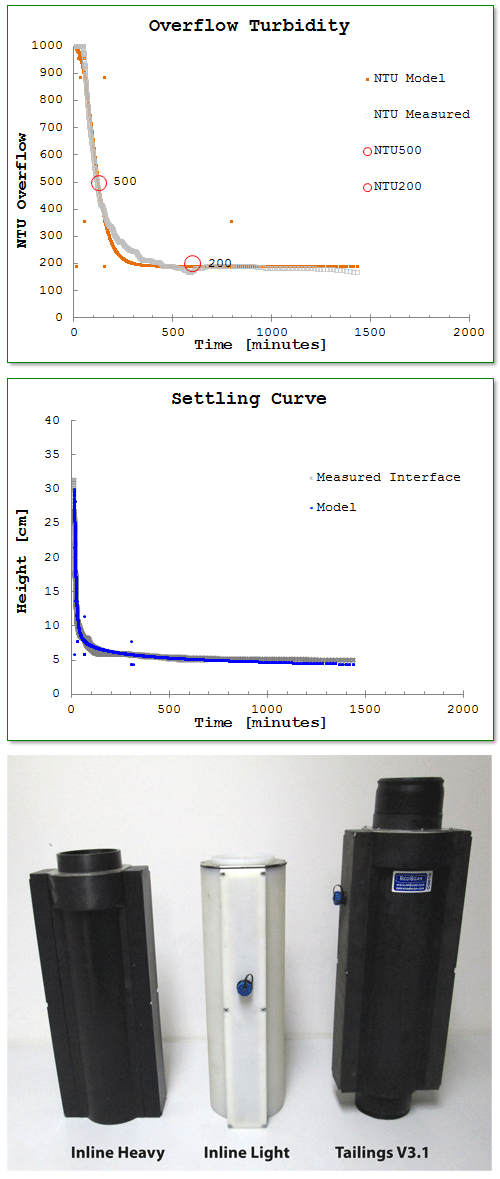

SedScan® is the first automated settling test developed to take away the technician and reduce the test error through the use of a control system and apparatus for measuring the performance of solid-liquid and liquid-liquid separation behaviour of slurries or pulps and liquids of variable density.

The equipment was developed in 2012 by a small consortium of international process engineers based on the need to improve accuracy of laboratory based tests that focus on characterising settling behaviour, primarily when dosed with additives that influence settling speed and density separation of the products under test. .

SedScan® was principally developed for the solid-liquid separation industries where thickeners and clarifiers are used to recover liquids from slurries and pulps such as those generated in the mining industry (tailings and concentrates) as well as waste water and potable water treatment. The technology can be applied to liquid-liquid applications such as the medical (blood settling) and oil refining industries.

SedScan® is patent pending and currently in development to be applied on both smaller and larger testing scales.

Theory

Improve the current methodology of performing a solid-liquid or liquid-liquid settling test by reducing human error and increasing data collection frequency, precision and overall accuracy.

Technology & knowledge

Allow for the simultaneous testing of multiple samples, considering the same standardised operating conditions and test parameters.

mobile design

The equipment has been developed to allow it to be transported between laboratories or remote locations as needed.

Protect your Models and Copyright!

Raw data is uploaded to a client based cload facility (of your choice), data processed and sent to the customer/client as readable data or final report.

Reduce Cost

Reduced cost compared to standard settling tests with increased data collection.